Crash

Simulating Crash Safety for Truck Cabins

Crash safety is one of the most essential points in the development process of truck cabins. Therefore a lot of safety requirements have to be considered.

For this special field of work the applicable safety requirements are covered by the No 29 regulation of the Economic Commission for Europe of the United Nations (UN/ECE).

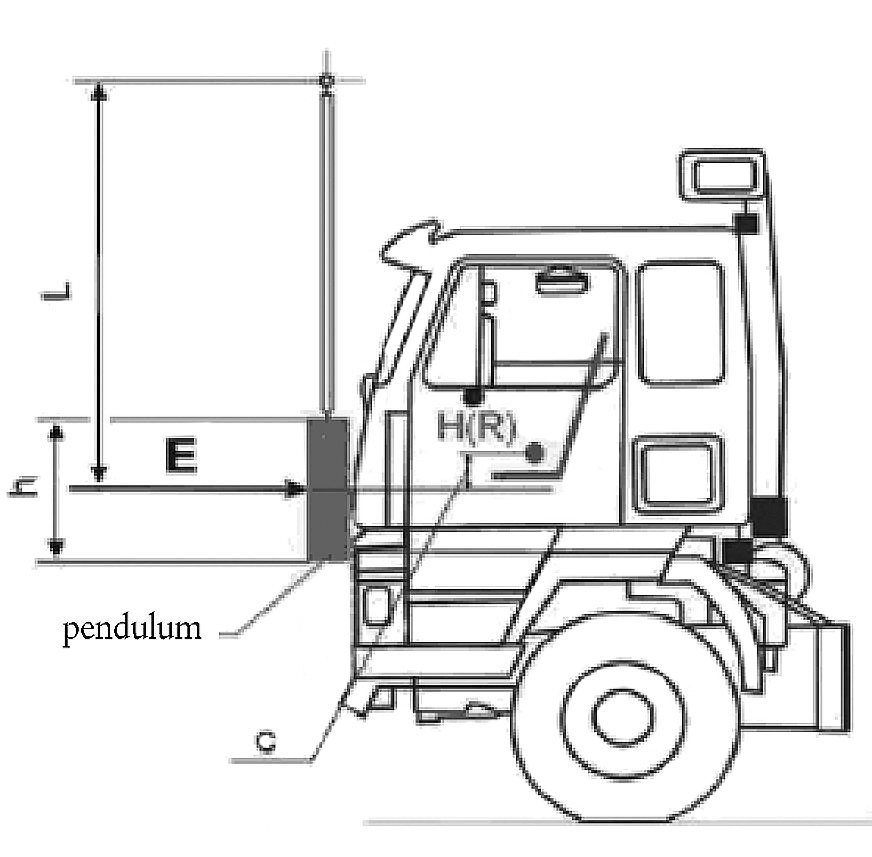

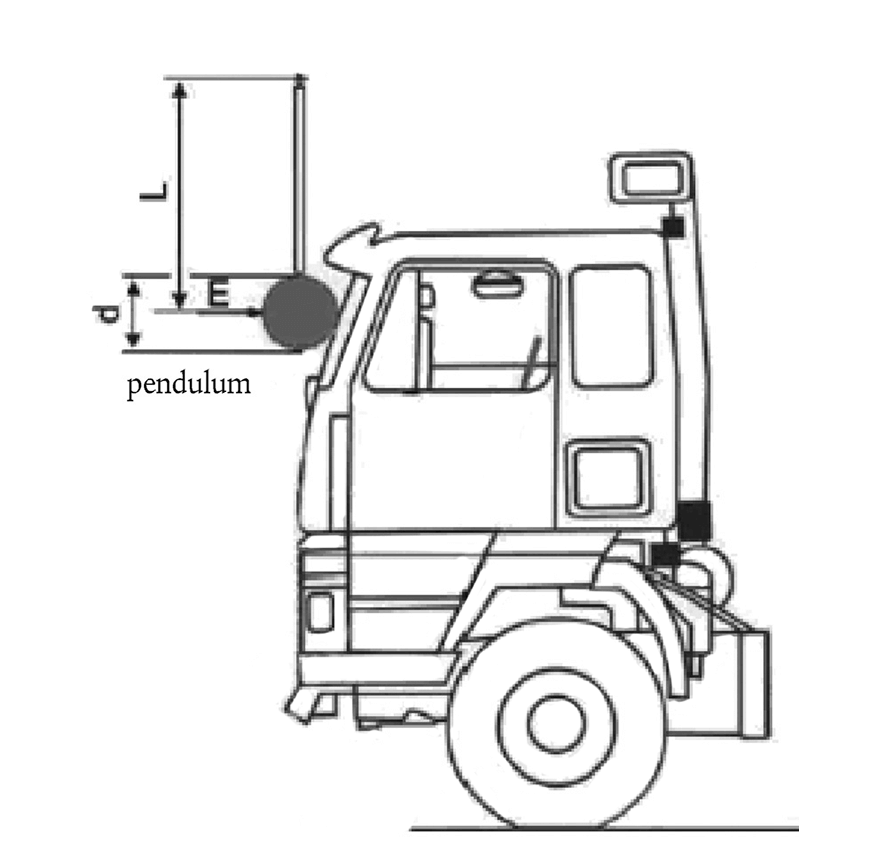

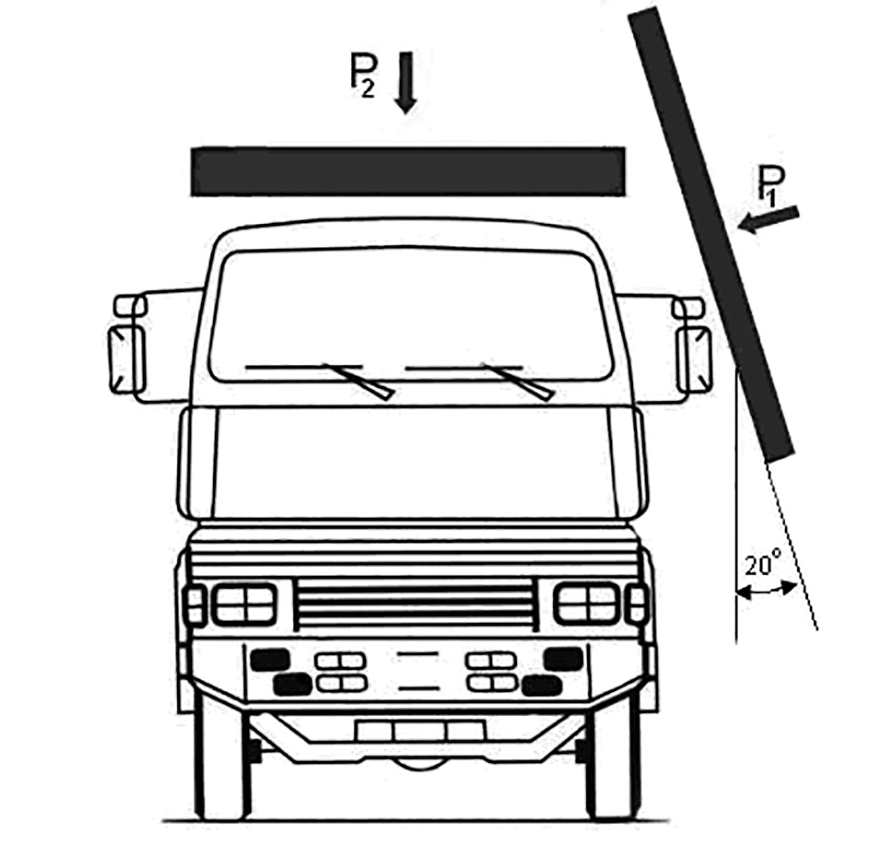

This regulation includes uniform provisions which cover the approval of vehicles with regard to the protection of the occupants. It consists of 3 tests which help to ensure survival space of driver and co-driver in a truck cabin.

All these three tests are passed if the following conditions are met:

- Adequate post-test survival space for the occupants

- Remaining connection of the cabin to the frame

- No opening of the doors during the test

The assessment of the last 2 conditions requires a reliable computation of the forces in the bolts, door hinges and door locks. Our engineers developed substitute models for the door hinges and door locks in order to enable an evaluation. Moreover a model which can take the bolt preload and the bolt failure into account was developed.

Evidence of compliance with ECE R29 can be provided by cost-intensive hardware tests, since tests A to C must each be carried out with a new cabin. However, ECE R29 also allows verification based on simulation results. This requires that the used calculation method is certified by an homologation institute like TÜV. Engineering Center Steyr (ECS) obtained this certification based on the comparison of the simulation results with the test shown in Figure 2. The transparent structure shows the synchronous simulation result.

The ECE R29 simulations are carried out with ABAQUS explicit. For the required material data (strain-rate-dependent stress-strain curves) our engineers can access their own database, which contains the usual standard steels and cast materials used for cabin and suspension brackets. If other materials are used for structurally relevant components, corresponding material data can be derived from similar materials.

Vehicle Side Crash Simulation

Another field of crash simulation in the truck sector is the side crash simulation. Here, the focus of the investigations is on the protection of the units required for new drivetrain concepts, such as battery boxes or H2 tanks. In contrast to the cabin crash, there are currently no sets of rules or standards for this application that define loads and compliance assessment criteria. For this reason, barrier models and crash scenarios from the passenger car sector are currently being adapted and the evaluation criteria are defined together with the OEM or suppliers.

Crash simulations are also becoming increasingly important in the truck sector. It is therefore constantly necessary to improve the methods, substitute models and material characterizations (keyword: connection techniques such as glueing) through regular research and development work.

Our Engineering Services

Due to the years of experience in the field of crash simulation in accordance with ECE R29 we can provide efficient support in the development process and save costs for homologation. Not all constructions immediately meet the criteria mentioned above.

In this case, based on the calculation results, the team develops suggestions for improvement together with the customer, which are evaluated in variant analyzes until all conditions are met. The correspondingly documented final results of the certified calculation process can be used to obtain ECE R29 homologation based on simulation results.