eDrive Testing

Advanced eDrive System Testing

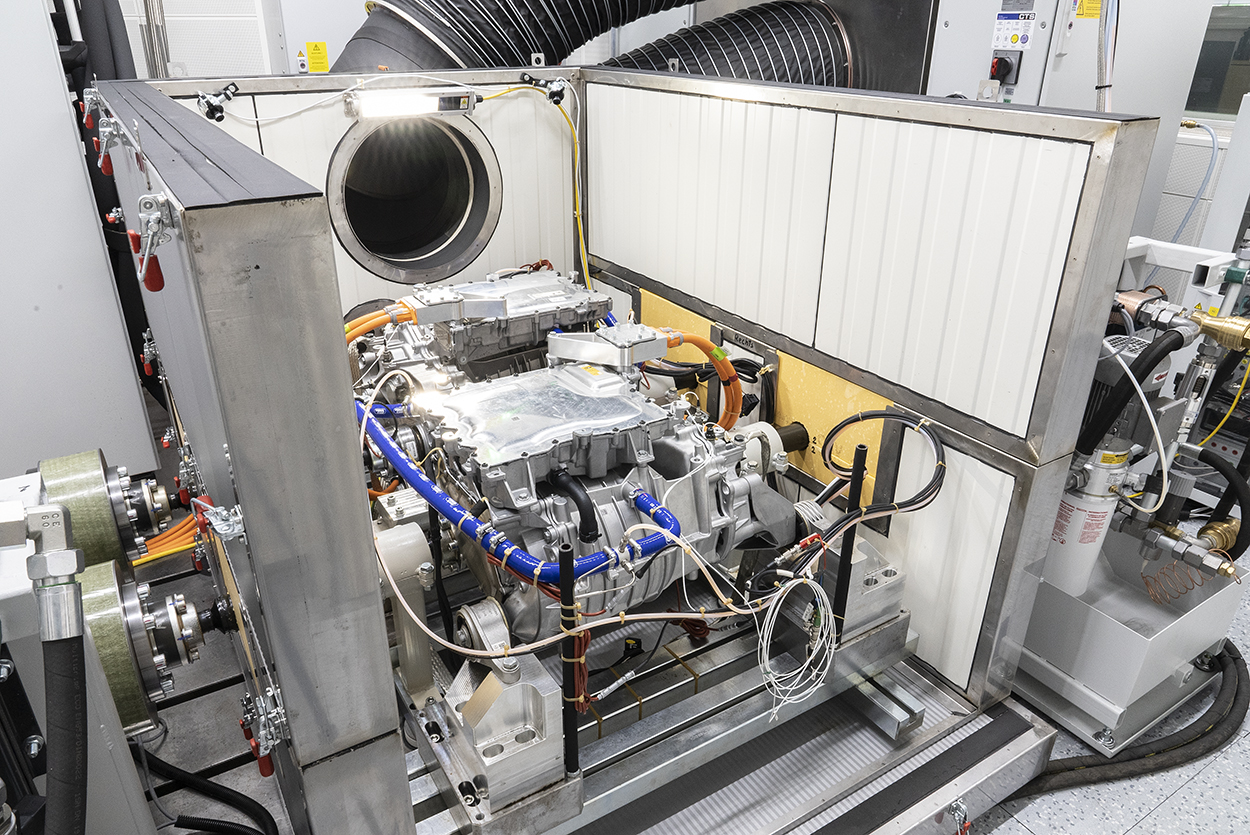

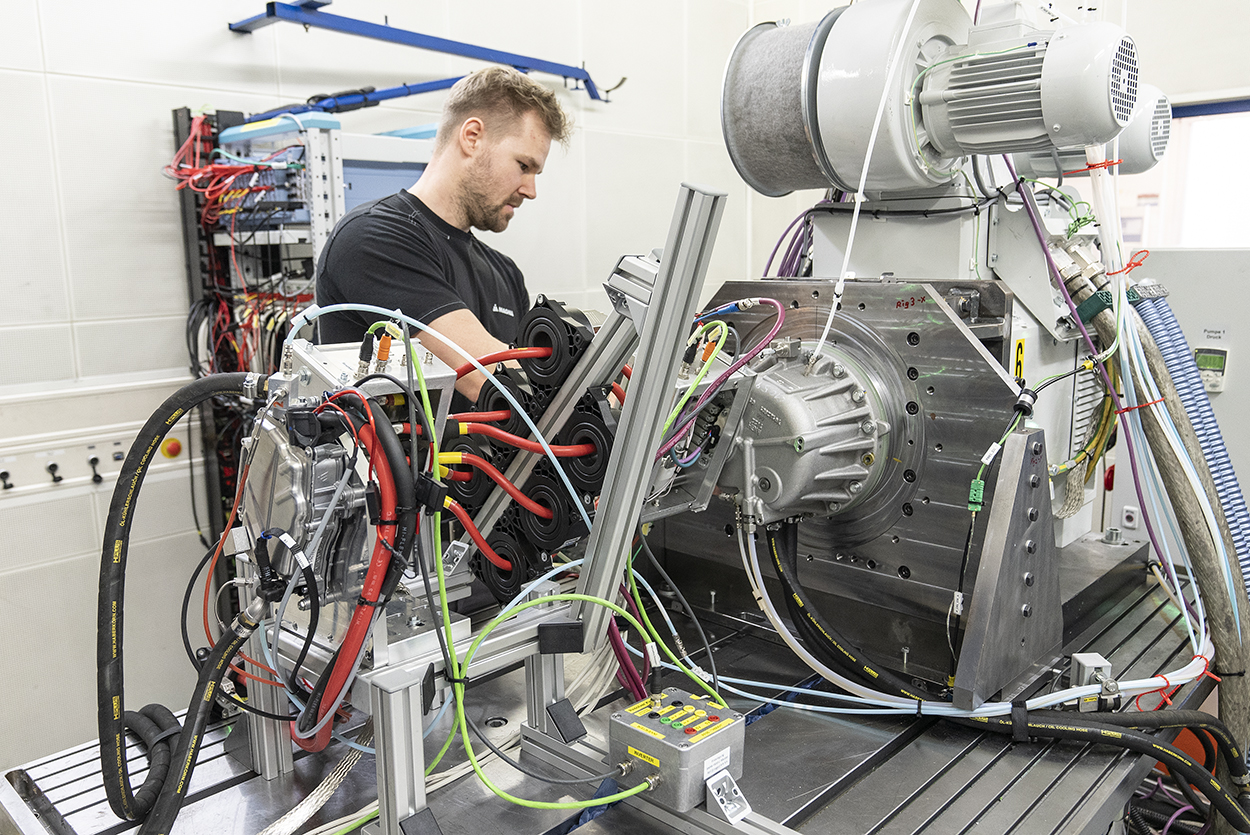

The business of eDrive testing at Engineering Center Steyr starts from prototypes up to serial products. The competence for new and derivative developments ranges from entire eAxle to a single eMotor. Installation of the DUT on the test bench allows to stress the eDrive system with pre-defined conditions.

The stress level can be adjusted, to the same conditions like normal road use and laboratory conditions. If necessary, a high speed gearbox can be fixed between DUT and the asynchron motor. Air and water conditioning is possible from -40°C up to +170°C.

The possibility to test an electric motor and inverter reaches from a simple eMotor tests to complete eAxle tests. The parallel test of two eMotors is configured by Back 2 Back structure.

In the last years we changed a big amount of the testing area into eDrive-testbenches, including a high climate chamber test bench. Here it is possible to set de DUT under additional controlled altitude and humidity. The measurement is implemented by high frequency measurement equipment to scale electricity and voltage.

Functional and Endurance Testing

- Component testing

- Benchmark

- System and functional testing

- Efficiency analysis

- Endurance testing

- NVH

- Engine speed < 20.000rpm

- Mechanical performance up to 529kW

- HV power supply (@1000V, 1200A)

- Water conditioning

- Air conditioning

- HBM torque flange

- LEM current transducers

- Yokogawa Precision Analyzer

- RedAnt

- 1-M eMotor

- 1-M eDrive

- 2-M eAxle

- B2B testing