KULI

Learn more about KULI

Thermal Management Simulation for an optimal Design of Cooling Systems regarding Safety and Efficiency

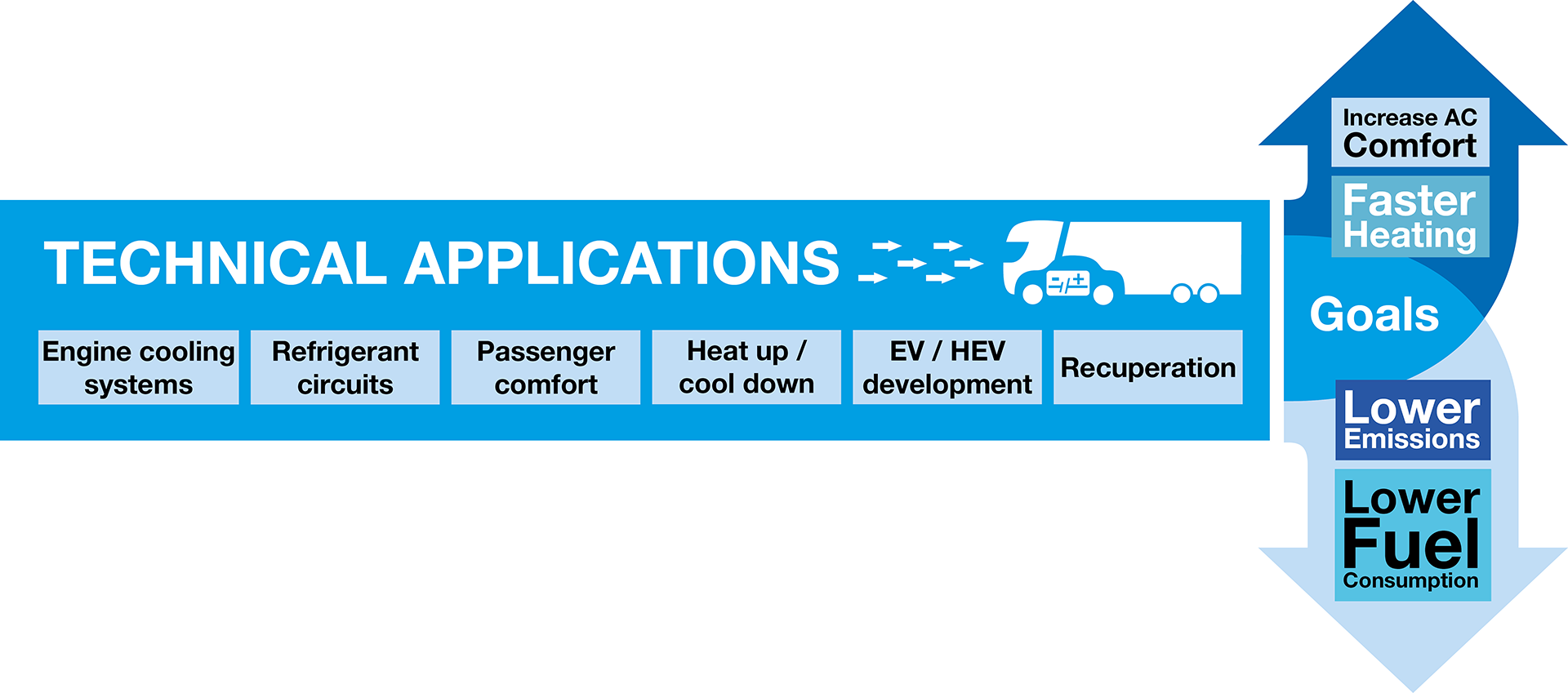

Thermal management simulation is essential in the development process of every new vehicle. Understanding how individual components influence the overall system is necessary for an optimal design regarding energy consumption, emissions, noise, fatigue, and other parameters. But the necessary expertise to perform the required sophisticated tests, simulations and calculations becomes more and more complex.

In today’s automotive industry two key drivers for new developments are safety and efficiency. This is not only true for the vehicle as a whole but can also be directly translated to most of its sub systems.

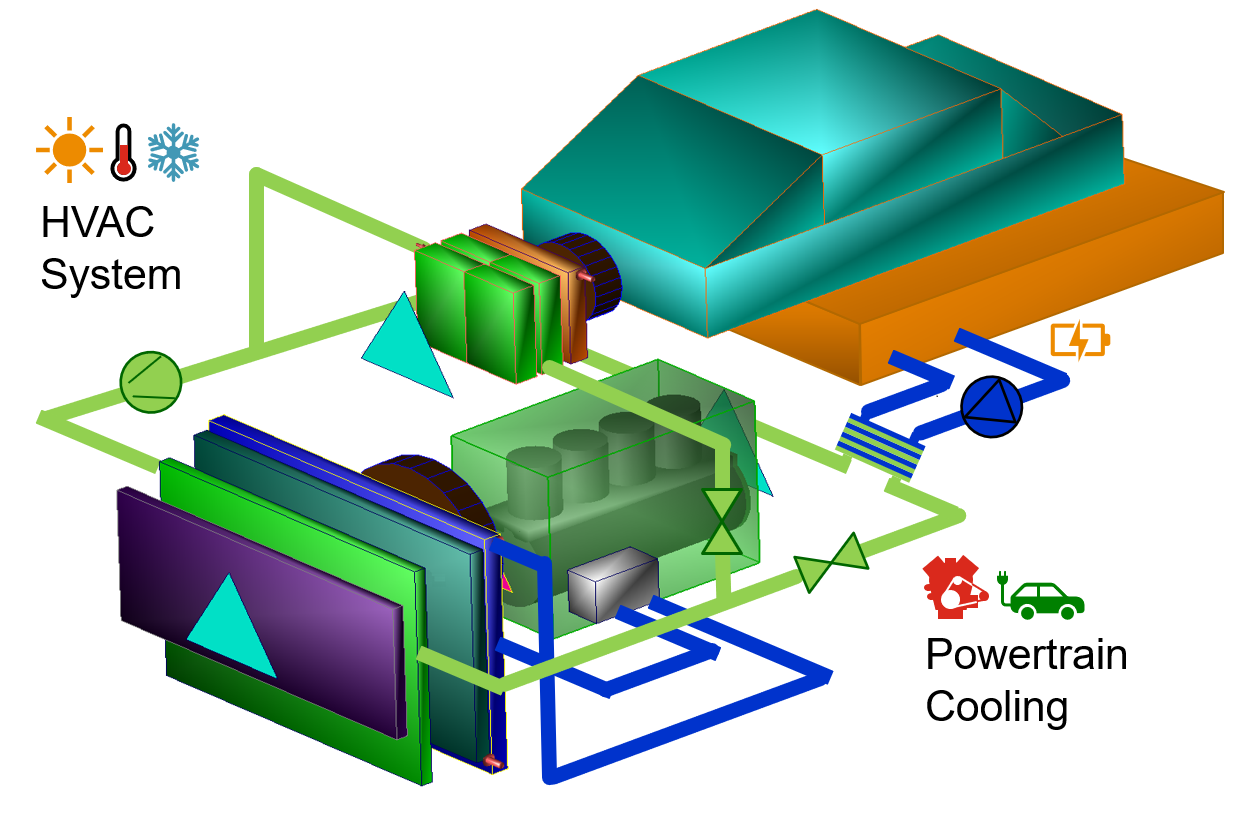

For thermal management systems safety means that all vehicle components (combustion engine, e-drive, battery…) can operate within their designated temperature ranges for all relevant vehicle operating points, driving cycles and ambient conditions. Efficiency means that this task is achieved with minimized energy effort. Adding passenger comfort as an important factor and also focusing on system cost minimization step by step reveals the complexity of modern cooling- and HVAC-system design.

KULI - A comprehensive System Level Simulation Software

A State-of-the-Art Development Tool for Engineers

During the concept phase engineers must consider different engines, gearboxes, heat exchangers, fans, carry-over parts, batteries etc. as well as control elements and actuators.

A general issue in state-of-the-art vehicle developments is the dimensioning of the cooling system to guarantee the required performance and emission levels. The Engineering Center in St. Valentin has developed the KULI simulation software to generate and optimize the thermal management system meeting all requirements on component-, system- and vehicle level. KULI assists in specifying and validating OEM requirements right from the start such as legal compliance, standards and regulations.

Thermal management has a high potential for improving fuel economy, reducing emissions and increasing efficiency of conventional, hybrid, electric and fuel cell vehicles. The wide experience at St. Valentin for engineering services in vehicle development allows us to continuously improve our KULI software for energy management simulation.

It’s still a main goal to keep all temperatures below certain limits to protect components against overheating. Moreover, it is essential e.g. for batteries to be operated in a certain temperature range for high efficiency and long lifetime. KULI can deal with all these challenges using appropriate simulation models of entire systems.

Also, the air conditioning system with detailed simulation options for the refrigerant circuit, the heat pump mode and the hot gas cycle are covered by KULI. In hybrid vehicles the air conditioning system is often used to cool the traction battery. The ‘Chiller’ component is the important link between coolant and refrigerant circuits. Integrated optimization procedures help the user to find the best layout. To keep up with the latest trends in vehicle development, software and simulation procedures are continuously enhanced.

Support of the Engineering Process