Fatigue Testing Service

Fatigue Testing Services

The fatigue testing services in St. Valentin offer a wide range of testing capabilities starting from small material specimen tests up to heavy duty commercial vehicle applications.

Our holistic approach in terms of collaboration of various services like simulation and testing allows us to gain the maximum added value for our customers. Material testing means much more than just evaluating fatigue life.

It is material analysis, method development and finally the derivation of innovative testing solutions. By doing so we can use FEM and MBS input data to tailor our test setups, reduce active channels by generating equivalent loads and determine internal forces for reduced hardware complexity. It is equally important to generate a loop from testing to simulation to sharpen simulation models and furthermore improve future development cycles. Therefore, the whole workflow from sensor application, load calibration, load spectrum generation, virtual iteration and finally the derivation of equivalent loads can be implemented.

After the derivation of appropriate loading conditions and specially tailored test rig concepts, single parts or whole devices may be loaded with up to 40 actuators simultaneously. Finally, structures and components from interest can be investigated by our NDT experts, in order to evaluate the most critically stressed regions regarding their characteristics after and during fatigue testing.

Equipment & Infrastructure

Examples of our Testing Services

Material Tests

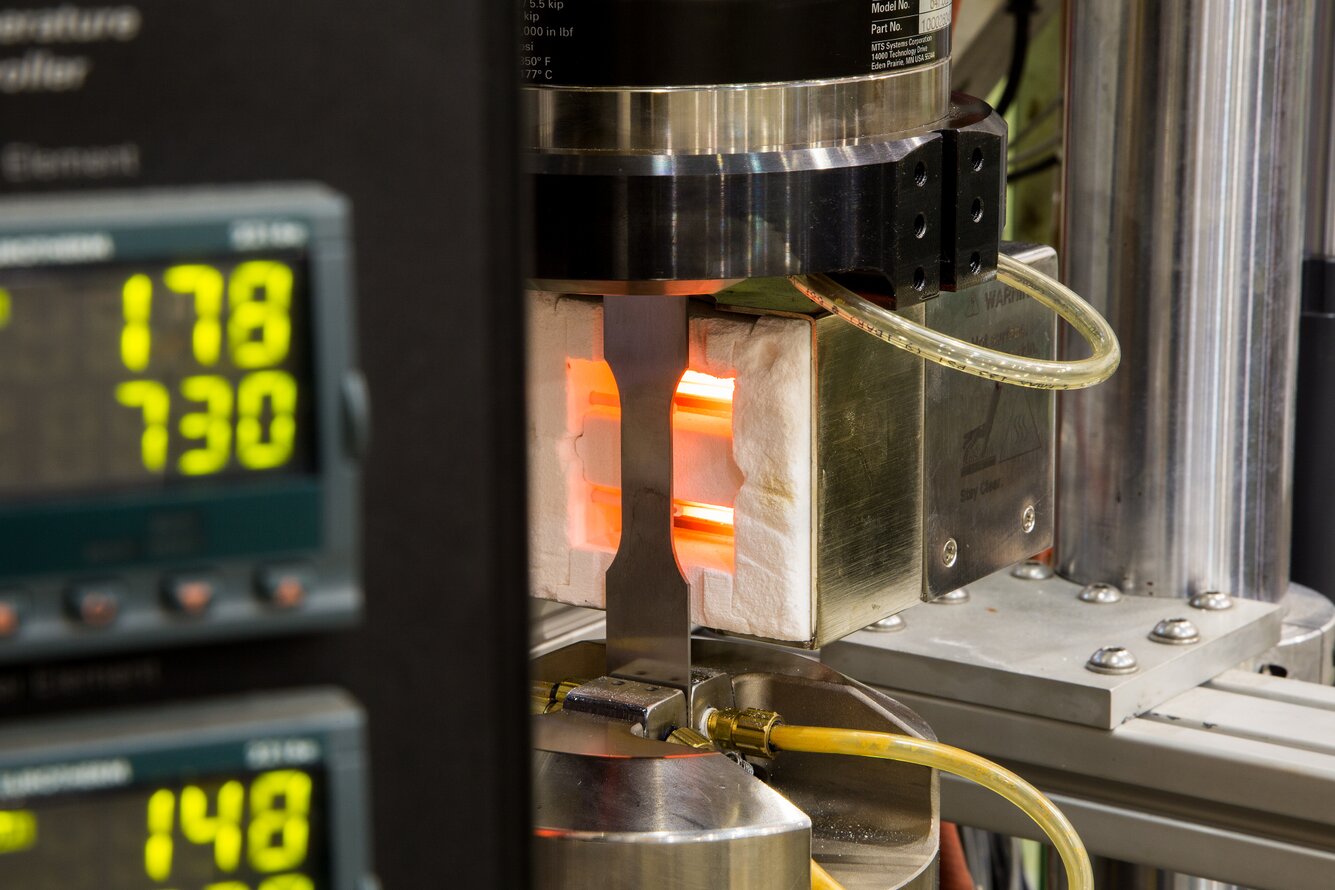

Evaluation of base material properties as well as properties of joints (weld, bond, ...) like

- Tensile tests

- Plastic deformation

- Low- and High Cycle Fatigue

- High temperature behavior (<1000°C)

Generation of material models for FEMFAT and FEMFAT WELD database.

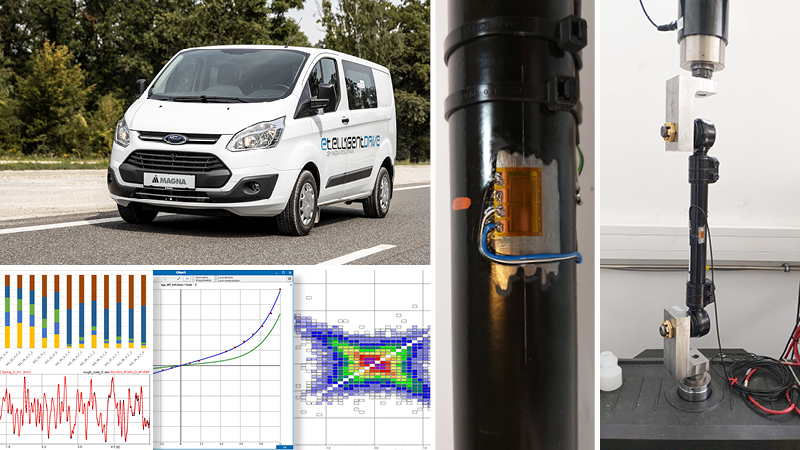

Load Data Generation & Measurement Services

The whole workflow from sensor application, load calibration, load spectrum generation, virtual iteration and finally the derivation of equivalent loads can be implemented.

The spectrum of our measurement services goes from standard load data measurements (strain, acceleration, displacement) to highly complex drivetrain efficiency measurements using telemetry equipment. Components are calibrated in-house for load data generation for internal as well as an external services. FEMFAT LAB is used to support the complete workflow of data generation and processing.